As a company produces items in small batches takes center stage, this opening passage beckons readers with gaya akademik dengan tone otoritatif into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Small-batch production has emerged as a transformative approach that empowers businesses to navigate the dynamic landscape of modern manufacturing. By embracing this method, companies can harness its potential to optimize production efficiency, enhance quality control, foster customization, and respond swiftly to market demands.

This comprehensive guide delves into the intricacies of small-batch production, exploring its advantages, challenges, and strategies for maximizing its benefits.

Production Method

Small-batch production involves manufacturing items in limited quantities, typically ranging from a few dozen to a few thousand units. This approach differs from mass production, where large volumes of standardized products are manufactured.

Advantages of Small-Batch Production

- Flexibility to respond quickly to changing market demands

- Reduced inventory costs due to lower production volumes

- Enhanced product quality due to increased attention to detail

Disadvantages of Small-Batch Production

- Higher unit production costs compared to mass production

- Potential delays in production due to smaller batch sizes

- Limited economies of scale

Industries and Products Utilizing Small-Batch Production

- Craft breweries and distilleries

- Artisanal food production

- Custom furniture and clothing

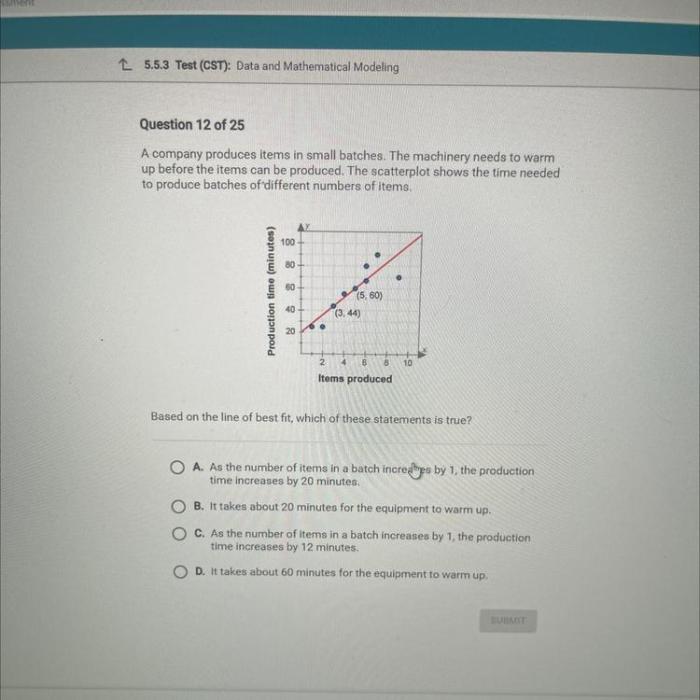

Efficiency and Cost

Small-batch production can impact production efficiency and costs in several ways.

Impact on Production Efficiency

Smaller batch sizes require more frequent production setup and changeovers, which can reduce overall efficiency compared to mass production.

Cost Implications

- Increased labor costs due to smaller batch sizes

- Higher material costs due to smaller purchasing volumes

- Reduced overhead costs due to lower inventory levels

Strategies for Optimizing Efficiency and Minimizing Costs

- Implementing lean manufacturing principles

- Automating production processes

- Negotiating bulk discounts for materials

Quality Control

Small-batch production can affect quality control processes in both positive and negative ways.

Advantages

- Increased attention to detail due to smaller batch sizes

- Reduced risk of defects due to closer monitoring

- Ability to quickly identify and correct quality issues

Challenges, A company produces items in small batches

- Consistency challenges due to variations in production conditions

- Increased reliance on skilled labor

- Potential for human error

Best Practices for Ensuring High-Quality Products

- Establishing rigorous quality standards

- Implementing quality control measures throughout the production process

- Training and empowering employees on quality assurance

Customization and Flexibility

Small-batch production enables greater product customization and flexibility.

Role of Small-Batch Production in Product Customization

Smaller batch sizes allow manufacturers to accommodate customer-specific requests and produce products with unique features or specifications.

Benefits of Product Customization

- Increased customer satisfaction and loyalty

- Ability to meet niche market demands

- Enhanced brand reputation

Limitations of Product Customization

- Increased production complexity

- Potential for delays in delivery

- Higher production costs

Strategies for Managing Challenges Associated with Customization

- Developing modular product designs

- Implementing flexible production systems

- Collaborating closely with customers on product specifications

Essential Questionnaire: A Company Produces Items In Small Batches

What are the primary advantages of small-batch production?

Small-batch production offers numerous advantages, including increased flexibility, improved quality control, enhanced customization options, reduced waste, and greater responsiveness to market demands.

How does small-batch production impact production efficiency?

While small-batch production may require more frequent changeovers, it can also lead to improved efficiency by reducing setup times, minimizing waste, and enabling more targeted production planning.

What are the key challenges associated with quality control in small-batch production?

Ensuring consistent quality in small-batch production requires robust quality control processes, effective training, and continuous monitoring to identify and address potential issues early on.